Test sieve shaker

Test sieve shaker

Vibrating sieve shakers from NEXOPART for dry and wet bulk materials in the measuring range from 20 μm - 125 mm

The vibrating sieve shaker from NEXOPART of the EML series and UWL are specially developed for the precise separation and classification of dry and wet bulk materials. They can be flexibly adapted to different types of bulk materials, so that materials can be analysed reliably and in accordance with standards – regardless of shape, size or composition. They ensure a high throughput while maintaining measurement accuracy. They also impress with their robust design and easy handling, which makes the user process much easier.

Vibrating sieve technology for laboratory applications: 3D sieving for your particle analysis

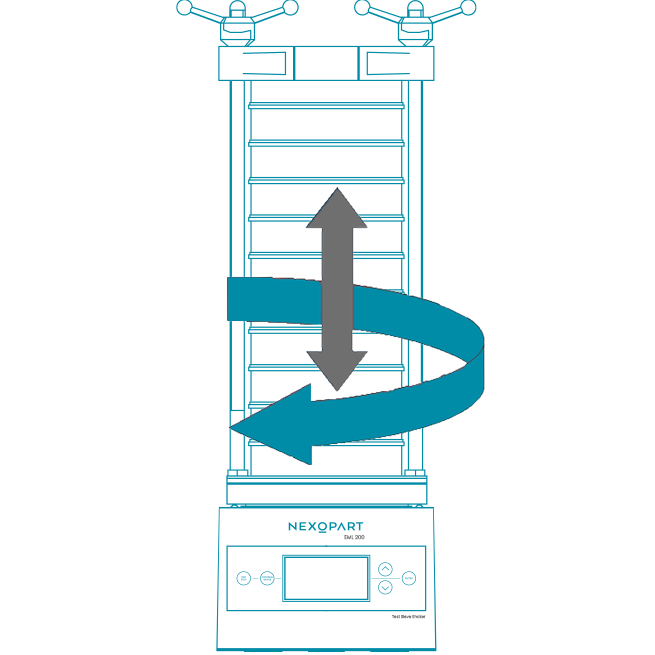

Three-dimensional machine sieving is one of the most well-known and proven methods of analytical sieving. It is also called "throwing sieving" because the test sieve or an entire sieve tower on it is simultaneously set into a vertical and horizontal rotational movement. This will throw all the particles upwards. As soon as the test sieve returns to the starting position, the particles have a chance to pass through a sieve opening when they fall. Particles that do not pass through the sieve are accelerated upwards again with the next movement and are given another opportunity to fall through.

Differences between wet sieving and dry sieving

Wet sieving:

L

Dry sieving:

L

The right steps for successful vibratory sieving:

- Sample preparation: the sample should be dry and free of agglomerate.

- Sieve selection: Sieves with graduated mesh sizes are stacked on top of each other in a sieve tower, whereby the following applies: mesh sizes from coarsely top to fine bottom, sieve pan to the very bottom.

- Weigh the sample: The total mass of the sample is determined before the start.

- Filling and sieving: Place the sample on the top test sieve, clamp the sieving tower firmly on the vibrating sieve shaker, adjust the sieving time, interval and amplitude.

- Sieving: Vibrating sieve shaker separates the sample according to grain size, particles remained on the test sieve, the mesh size of which is smaller than their grain size.

- Evaluation: The material on each test sieve is weighed. From this, the percentage grain distribution is calculated. Results are documented.

NEXOPART vibrating sieve shakers certified according to DIN EN ISO 9000

The vibrating sieve shakers from NEXOPART are testing and measuring equipment that are certified and tested according to DIN EN ISO 9001 ff. Regular inspections of the shakers ensure their function, safety and perfect condition. This ensures long-term and standard-compliant quality assurance. After successful testing, the vibrating sieve shakers from NEXOPART receive a seal of approval as well as an acceptance test certificate 3.1 in accordance with DIN EN 10204.

Models and Features of NEXOPART Vibrating sieve shakers

EML 200 Pure:

L

• Easy to use (plug and play)

• Two hard-coded amplitudes (fine 0,9 and coarse 2,2)

• Predefined interval (every 10 sec.)

• Sample weight of up to 3 kg

• Voltage: 110 - 230 V, 50 - 60 Hz

• Dimension W x D x H: 385 x 295 x 895 mm

• Weight: 37 kg, net

• Sieve diameter up to 203 mm

• Cover with inspection glass

• Only for dry sieving

Application: The EML 200 Pure is particularly suitable for laboratories or for applications where simple dry sieving with the classic clamping system is sufficient. It comes in proven quality at an affordable price.

Buy the EML 200 Pure from Nexopart now.

EML 200 Premium:

L

• Individually adjustable amplitudes (freely selectable up to 3 mm)

• Individually definable intervals

• Sample weight of up to 3 kg

• Voltage: 110 - 230 V, 50 - 60 Hz

• Dimension W x D x H: 385 x 295 x 895 mm

• Weight: 37 kg, net

• User-friendly display

• Available with two different clamping systems: TwinNut and Classic

• Sieve diameter up to 203 mm

• Cover with inspection glass

• Only for dry sieving

Application: The EML 200 Premium is very suitable for laboratories or for applications where simple dry sieving is required with more options for freely adjusting the amplitude and interval. It comes in robust quality at a good price.

Check out the EML 200 Premium from Nexopart here.

EML 200 Premium Remote:

L

• Individually adjustable amplitudes (freely selectable up to 3 mm)

• Individually definable intervals

• Sample weight of up to 3 kg

• Voltage: 110 - 230 V, 50 - 60 Hz

• Dimension W x D x H: 385 x 295 x 895 mm

• Weight: 37 kg, net

• Separate control unit with user-friendly display

• Available with two different clamping systems: TwinNut and Classic

• Sieve diameter up to 203 mm

• Cover with integrated full cone nozzle

• Suitable for wet and dry sieving

Application: The EML 200 Premium Remote is specially developed for wet sieving. It is equipped with a separate control unit and also offers the option of safe dry sieving. This makes it ideal for laboratories that want the option of wet and/ or dry sieving. It comes in the best quality at a good price.

Shop the EML 200 Premium Remote from Nexopart now.

EML 315:

L

• Individually definable intervals

• Sample weight of up to 6 kg

• Voltage: 110 - 230 V, 50 - 60 Hz

• Dimension W x D x H: 404 x 440 x 1000 mm

• Weight: 55 kg, net

• Separate control unit with user-friendly display

• Available with two different clamping systems: TwinNut and Classic

• Sieve diameter up to 315 mm

• Cover with wide spreading spray diffuser

• Two types of machines available: for wet sieving (digital plus N) + for dry sieving (digital plus T)

Application: The EML 315 is particularly suitable for laboratories or for applications where heavy bulk materials up to 6 kg with test sieves with a diameter of 200 - 315 mm are used.

EML 415:

L

• Individually definable intervals

• Sample weight of up to 15 kg

• Voltage: 110 - 230 V, 50 - 60 Hz

• Dimension W x D x H: 585 x 575 x 1300 mm

• Weight: 135 kg, net

• Separate control unit with user-friendly display

• Available with two different clamping systems: TwinNut and Classic

• Sieve diameter up to 450 mm

• Cover with wide spreading spray diffuser

• Two types of machines available: for wet sieving (digital plus N) + for dry sieving (digital plus T)

Application: The EML 450 is equipped for laboratories or for applications where heavy bulk materials up to 15 kg are used with test sieves with a diameter of 200 - 450 mm.

UWL 400:

L

• Easy to use (plug and play)

• 1500 oscillations per minute

• Sample weight of up to 20 kg

• Voltage: 200 - 240 V, 50 - 60 Hz

• Dimension W x D x H: 600 x 600 x 1420 mm

• Weight: 190 kg, net

• Separate control unit

• Available with three different clamping systems: TwinNut, Classic and clamping system for beechwood frames

• Sieve diameter up to 450 mm

• Cover with wide spreading spray diffuser

• Suitable for wet and dry sieving

• Three types of machines available: for wet sieving (N) + for dry sieving (T) + for beechwood frames (H)

Application: The UWL 400 is specially developed for large and heavy bulk materials up to 20 kg. It is NEXOPART's most powerful 3D test shaker and offers the option of dry and wet sieving as well as sieving with beechwood frames.

Advantages over other sieving machines:

Application for laboratory analyses

- Building materials industry: Analysis of sand, gravel, cement, mineral raw materials and aggregates.

- Chemical industry: Quality control of powders and granules.

- Pharmaceutical industry: particle size analysis of active ingredients and excipients.

- Food industry: Examination of flours, sugar and other bulk materials.

- Environmental and recycling laboratories: sieving of soil samples and secondary materials.