Air jet sieve machine

Air jet sieve machine

The e200 LS air jet sieve machine from NEXOPART for the finest and agglomerating powders in the measuring area from 10 μm - 4 mm

The e200 LS air jet sieve machine is specially designed for the separation, fractionation and grain size determination of fine to very fine powders. Fine powders have a greater tendency to agglomeration. This makes sieve analysis unnecessarily difficult. The advantage of the NEXOPART e200 LS is that when fine powders or oily particles clog the test sieve, it skilfully dissolves the agglomerations. The e200 LS air jet sieve machine is therefore ideal for various industries, including the mineral, chemical and pharmaceutical industries (in compliance with the requirements of 21 CFR Part 11), toner production, food and beverage production as well as the cement and building materials industries. With quiet operation, high speed and efficiency, it delivers accurate measurement results with high reproducibility.

Air jet sieving: The best method for particle analysis of the finest powders

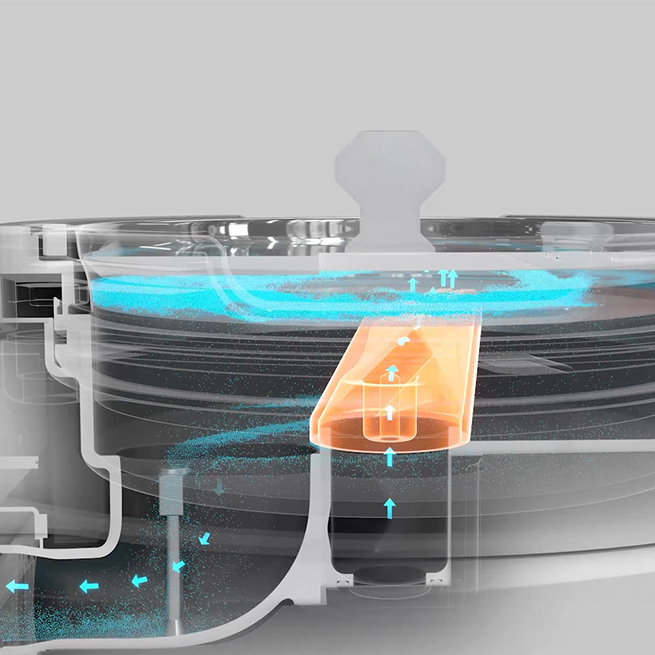

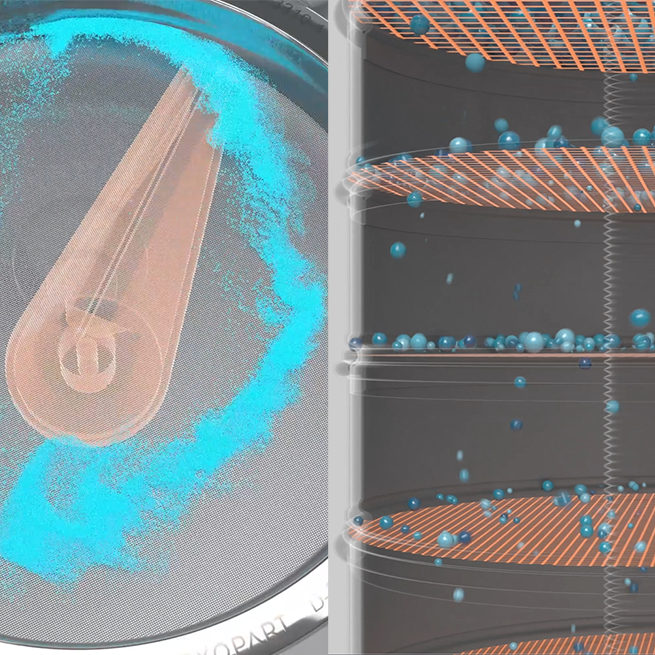

Air jet sieving is a process that effectively separates fine, dry particles with the help of an air stream. The sample material is evenly distributed on a test sieve with fine meshes and closed with a lid. In the sieving chamber of the NEXOPART e200 LS, a rotating slotted nozzle works together with an externally connected industrial vacuum cleaner. With the help of the vacuum cleaner, a vacuum is created in the sieving chamber of the e200 LS, while the narrow gap of the slot nozzle accelerates the air masses that flow through the sieve mesh from below. The air jet keeps the particles moving and agglomerates are broken up. As a result, even very small particles can safely pass through the sieve openings.

Features of the e200 LS air jet sieve machine:

- High reproducibility and comparability

- Automated user guidance 4 software packages: LITE, BASIC, ULTIMATE, SECURITY

- Sample weight up to 30 g

- Negative pressure (Pa): 1500 - 5000

- Voltage: 90 - 264 V, 50/60 Hz

- Dimentions L x W x D: 535 x 370 x 386 mm

- Weight: approx. 17 kg, net

- User-friendly touch display

- Manual sieving, sieving according to SOP (Standard Operation Procedure with 2 GB of storage space)

- Test sieve management

- Automatic sieve identification (RFID)

- 13 languages (EN, DE, FR, ES, IT, CS, JA, PT, RU, TR, ZH, PL, HU)

- Archive for calling up and evaluating the stored sieving processes

- Scale management for external scales, protocols for specific scales Kern, Sartorius, Mettler and Ohaus are stored and can be connected via USB or RS232. Further drivers can be added at any time according to customer-specific requirements.

- Integrated sieve cleaning

- Only suitable for dry sieving

- 100% Made in Germany

The single steps for successful air jet sieving:

1. Sample preparation:

L

• The weighing is carried out. The material is measured before sieving

Shop the right laboratory balnce at Nexopart now.

2. Filling the material:

L

• A defined amount of max. 30 g of the powder is placed on the fine sieve.

Find the perfect test sieve from Nexopart here.

3. Start of the air jet sieving process:

L

• A high-performance industrial vacuum is connected, which creates an air flow or vacuum in the sieving chamber of the machine.

• The airflow creates a vortex motion that loosens the powder and breaks up agglomerates.

4. Sieving process:

L

• Finer particles pass through the sieve openings and enter the vacuum cleaner bag or a collection container.

• Coarser particles remain on the sieve.

5. Continuous control:

L

6. End of the process:

L

• The sieve is removed and the coarser particles are weighed and/or further processed.

• The fine particles are collected separately.

7. Evaluation:

L

• In production processes, the particles are used directly.

Advantages and specifications over other test sieve machines:

Features: Air jet sieve machine vs. vibrating test shakers

The air jet sieve machine differs from vibrating sieve shaker by its operating principle:

- The material is placed on a single fine sieve.

- An air jet, instead of vibration, creates a vacuum in the machine's sieve chamber through an interaction between an industrial vacuum cleaner and a rotating slot nozzle.

- The airflow dissolves agglomerates and keeps the particles moving, making them easier to fall through the sieve openings.

| Air jet sieve machine | Vibrating test shakers | |

| Principle | airflow releases agglomerates and moves particles | mechanical vibrations move the particles |

| Material | dry, fine powders | powders, granules, even coarser materials |

| Measuring range | very fine 10 µm – 4mm | from coarse to medium 20 µm - 125 mm |

| Load on the material | very gentle | mechanical stress |

| Areas of application | pharmaceuticals, chemicals, food, metal powders | building materials, recycling, food, chemicals |

| Design | single test sieve + air nozzle | multiple sieves stacked in a sieve tower + vibration motor |

| Pros | precise, ideal for fine powders | high throughput, versatile for dry and wet sieving |

| Cons | only suitable for dry powders | less suitable for extremely fine powders |

Differences between the four software packages: LITE, BASIC, ULTIMATE UND SECURITY

Whether its demanding tasks with high throughput in the mineral and cement industry or strictly regulated and documentation-intensive processes in pharmaceutical and food production: eControl's four high-performance software packages offer the right solution for every process engineering requirement. Regardless of your personal software choice, the LITE version is always available pre-installed on the devices. However, a software upgrade is possible at any time. All that is provided is a new license key, which can be activated quickly and easily on the device. The NEXOPART team is happy to design an individual software package that is precisely tailored to your requirements.

LITE:

L

• For quick and easy analysis

• Simple one-touch operation

• Graphic user interface

• Display of the underpressure (in Pa), sieving time, date and time

• Manual underpressure control

BASIC:

L

• Fast, simple evaluation of the results, prepared in table form

• Balance communication via RS-232 interface

• Central parameter management of all sieves

ULTIMATE:

L

• Automatic saving and printing

• Sieve set management (SOP)

• Result evaluation against setpoint specifications (table and graph form)

• Automatic backup

• Individualized level of detail

• Various chart types

• Parameter management for each test sieve

SECURITY:

L

• Requirements for software validation as classified in ISPE GAMP 5, FDA 21 Part 11, compliant with EC GMP Annex 11

• User management

• Password management

• Audit trail – user activity monitoring and event logging

• E-signature

• Network connection required

Areas of application for laboratory analyses

- Pharmaceutical Industry: Validated particle size throughput for microfine active ingredients, excipients by covering 21 CFR Part 11

- Chemistry: Pigments, powders

- Food: Separation of flour-like powders such as cocoa powder, coffee powder, flour, starch, etc.

- Additive Manufacturing: Metal Powder

- Toner production

- Cement and building material applications: Fast and reproducible analyses of grain size in the building materials laboratory.

Accessories for the air jet sieve machine

NEXOPART offers special accessories for sample preparation, cleaning and tools for actual analysis.